Quarrying

We are the new alternative and we are market innovators, Chariot International embraces the opportunity to work with you on your orders and we guarantee your satisfaction.

We are saying that we are your number one choice for the finest quality (consistently), selection (unsurpassed), service (reliable), and cost (value-saving).

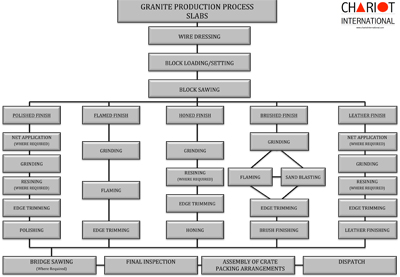

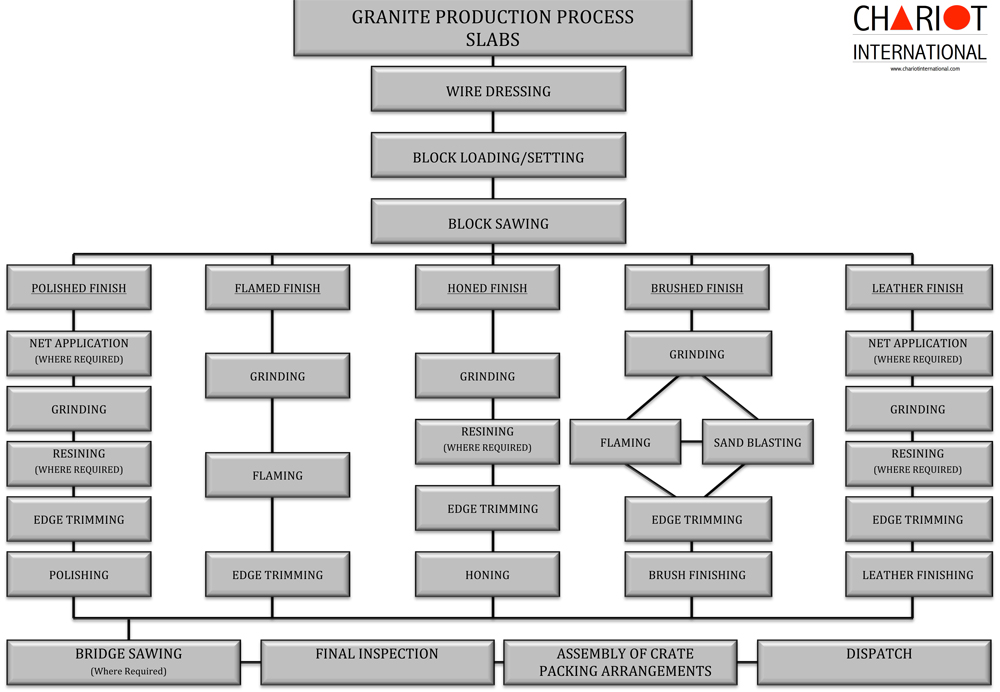

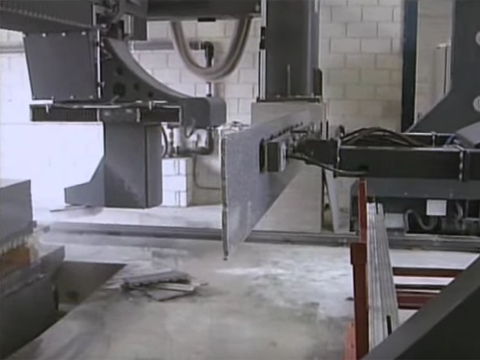

Processing

Granite Slab Production

Our slab factories meticulously take care of block unloading, polishing, cleaning and stacking of polished slabs.

These cut slabs are then cleaned thoroughly with water and sent to the 21 head automatic line polisher which polishes the slab and gives a gloss of + 90 in most cases. This polished stone is sent for the next step of stringent inspection where we check for consistency in the thickness of the slabs, the polishing, the gloss (we check individually each slab with a Gloss Meter) and scrutinized for any hairline cracks or swirl marks.

Followed with one of the last steps which is to measure right angle from all sides and an allowance of 3cm is given on all sides as part of our policy of giving extra value to all our customers. Only those slabs meeting our inspections are then ready to be sent to our online shipping center. The export warehouse, next to the internal port, so as to ensure quick and prompt deliveries.

Utmost care is taken on packaging so as to ensure the safe delivery of the stone once it leaves us and is shipped. The slabs are packed airtight in open or closed top containers with foam sheets in between polished slabs.

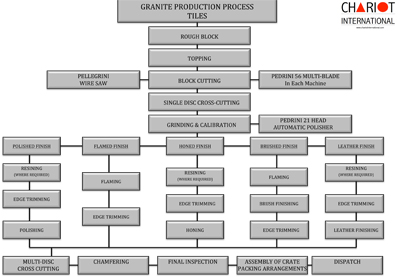

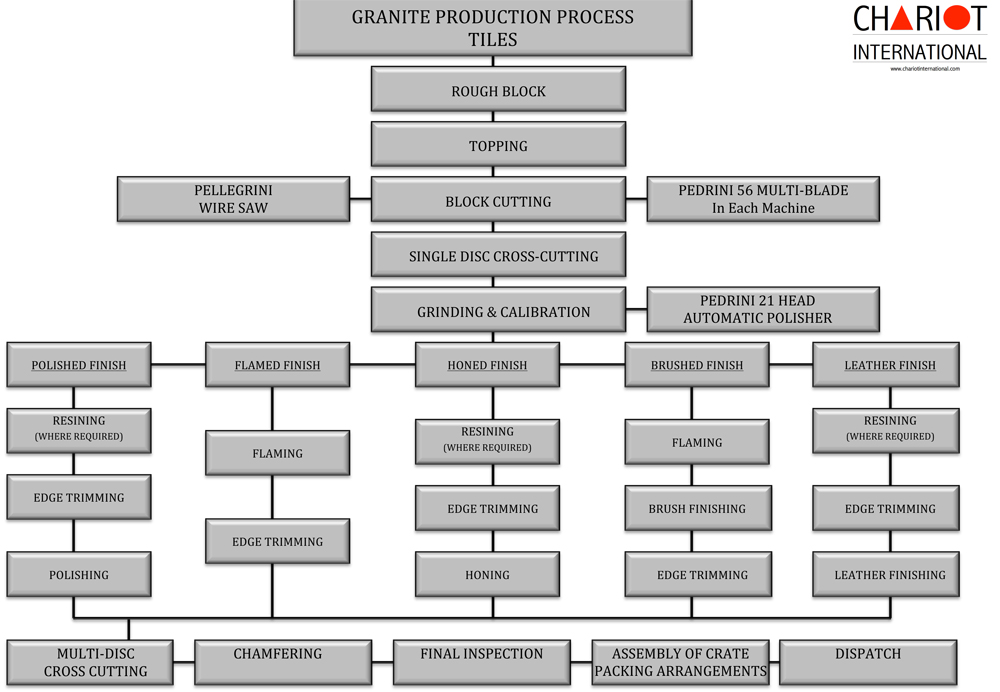

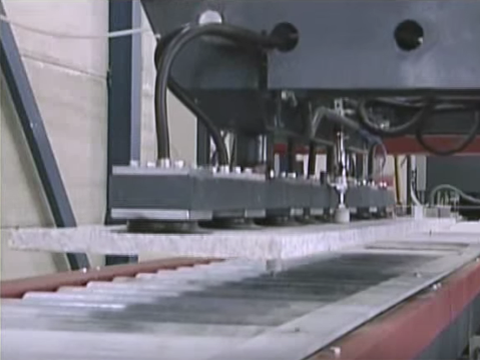

Granite Tiles Production

Each process at our factories are fully automated with the latest Italian Equipment. In terms of efficiency and standards of quality, we are by far ahead of most companies in India. This 20 head polishing machine grinds, polishes and give gloss to the stone before the tiles are cut to the required sizes, and then the final finishing takes place on the surface of the tile. The stones are available in a range of 8 smooth and textured finishes. This is achieved by polishing, honing or flaming to the tile. Chamfering smoothes the edges of the stone and then the dried and buffed stone is exposed to the most stringent of inspections, high above industry standards. The material, the grain, and the polish of each individual tile comes under intense scrutiny with our trained inspectors before it is sent for packing.

Packaging

Slab Packing

A-frame packing

35 slabs 0f 2cm or 26 slabs of 3cm on both sides of A-frame.We can put up to 7 bundles/crates/pallets in a 20' container either open top or closed top. Again it depends upon the weight of each pallet/bundle. Which container i.e. open top or closed top depends on the customer requirement.

Cut to size slabs

Based on the dimensions of the slab sizes and customer's preference. We are glad to handle any requested size need that you may require, that is one of our specialties.

A-Frame is made of steel (Gauged thickness) and has reinforcement bars to handle all the weight all A-Frames are totally secured in the container. then slabs are loaded with foam separation to avoid any possible shipping situations

All materials are totally reinforced to avoid any possible damages in shipping. WE work here to make every shipment trouble-free!

All orders of materials Tile or Slab will be loaded, according to your requirements but always maximizing the normal guidelines of allowable weight by all the steam ship lines.

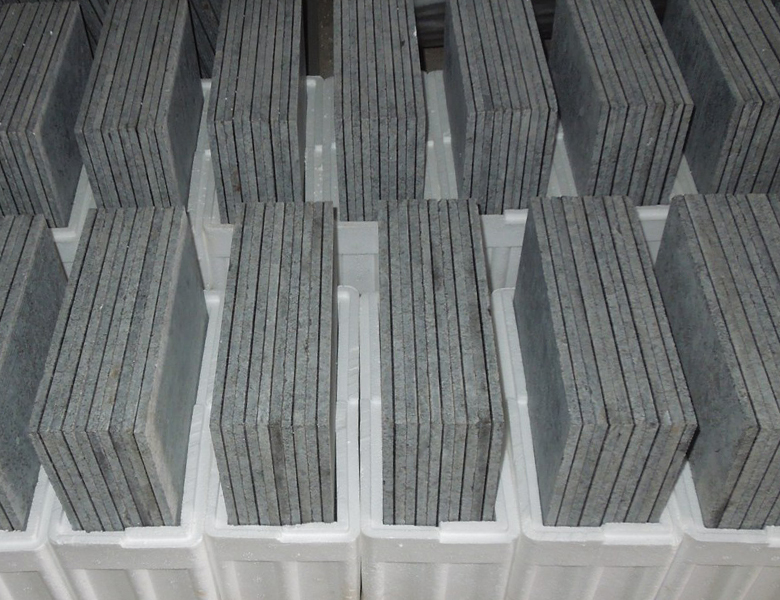

Tile Packing

12 " x 12 " Tile

10 Tiles are packaged in 1 box; 36 such boxes packed in 1 crate and 24 crates in one container. Total 8640 tiles = 1 Container.

16 " x 16 " Tile

6 tiles are packed in 1 box; 24 such boxes packed in 1 crate and 28 crates in a container. Total 4032 tiles in a container.

24 " x 24" Tile

Cut to size tiles

Based on the dimensions of the tile sizes & customer's preference

Logistics

:: Information of this area will be populated soon ::